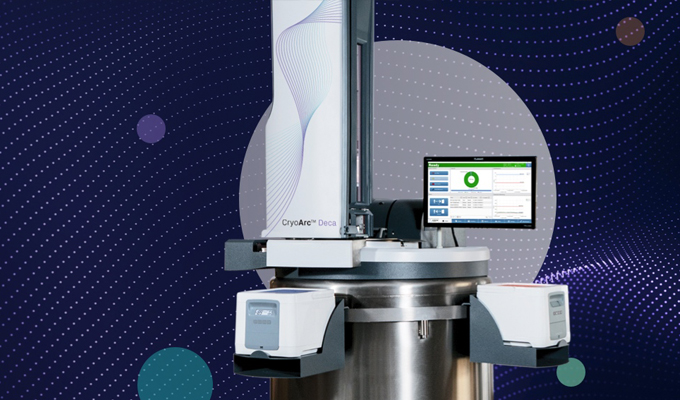

Protect your precious cryogenic samples in almost any sample vessel type from small to large. Your cryogenic sample storage workflows are eased through the robust, documented sample integrity protection along with user-friendly sample management and control provided by this automated cryogenic storage solution.

CryoArc Tera holds up to 630 cryoboxes, 3360 25ml cassettes, or 1680 50ml cassettes. This mix-and-match storage convenience is ideal for facilities managing many different sample types and research needs.

Tera is designed with a familiar high-efficiency LN2 stainless steel freezer along with an insulating sample transport robotic tower, and powerfully intuitive CryoArc Software. Together, these combined components boost efficiency in your automated cell and biological sample management workflows.

The Sample Experience

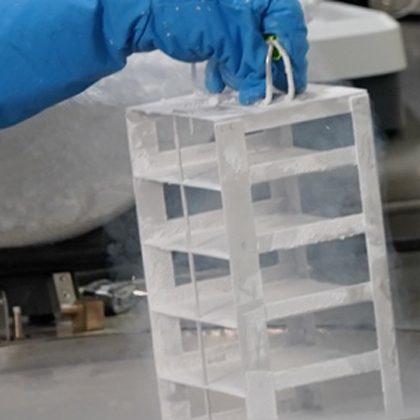

Sample boxes from 1 to 7 inches tall or cassettes placed into the insulated robotic tower are automatically delivered to user specified or system optimized locations within the CryoArc Tera. Inventory information is tracked at the tube, cassette, and microplate level, and can be shared with your facility’s LIMS.

The liquid nitrogen vapor phase provides a consistent -190 ºC temperature for stored samples from top to bottom. In case of electrical outages, LN2 interruption, or other unforeseen hazards, Tera provides amazing longevity, with up to 21 days of temperature stability to protect samples from harm. An onboard uninterruptable power supply (UPS) ensures all samples are safely stored in the event of power disruption, maintaining the storage environment and data integrity.

Targeted and non-targeted samples are protected from warming above Tg (glass transition temperature) both in storage and during retrieval by the insulated robotic tower and intelligent software controls. Every exposure is controlled and traced to ensure samples always remain below the critical temperature.

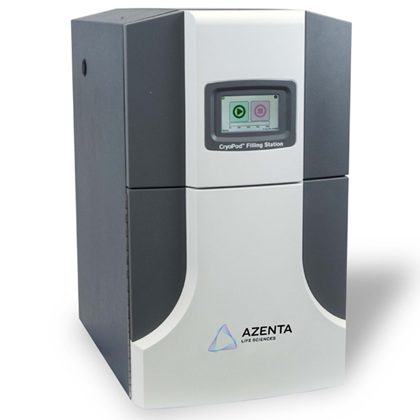

Optional CryoPod Carriers attach to the Tera’s rim to hold samples when they are removed from the sample transport robotic tower. These award winning cryo carriers maintain sample environment temperatures at less than -150ºC for over 3 hours, depending on fill level, heat load, and lid placement. This maintains confidence in sample integrity when transporting frozen cryoboxes or cassettes or preparing to use samples at a workstation. Temperature, date, and time are logged, and users are alerted if temperature ranges are breached.

The User Experience

CryoArc Tera’s no-hassle sample placement and retrieval process and ergonomic vending machine styled design protects users from the physical stress and strain of leaning over a storage tank and also helps to minimize personal protective equipment requirements.

A friendly touchscreen graphical user interface empowers users of any skill level to effortlessly manage detailed sample inventory and rapidly execute orders. User permission levels prevent accidental sample access while empowering diligent record-keeping, enabling the Tera to become a shared resource.

The Data Experience

CryoArc software uses an optional WebAPI module to seamlessly integrate with any homegrown or enterprise LIMS. In addition to smooth data flow, CryoArc Tera supports adherence to FDA 21 CFR, Part 11 requirements to satisfy regulatory demands, if required. All sample, chain-of-custody, and performance data may be downloaded in a standardized format for inclusion in audit reports.

Key Features

Easily Control and Manage the Details

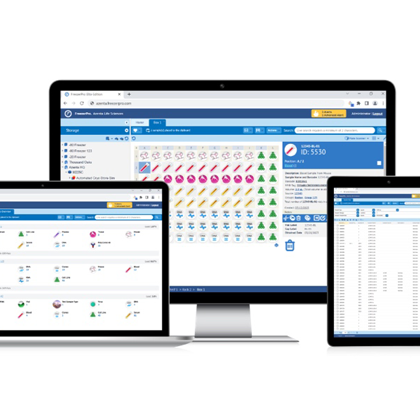

Cryo critical software platforms from Azenta are vital to your cold chain management strategy.

Integrated CryoArc Software:

- Tracks individual sample location, sample movement, and user access over the sample’s lifetime

- Captures real-time environmental data including temperature, unexpected events, alarms, LN2 usage, and LN2 levels

- Supports 21 CFR Part 11 compliance

- Optional library management allows users to partition the storage space and assign access privileges to individual or groups of users

- Optional alerts management enables custom alert configurations and notifications via email or mobile devices in response to system behavior

Remote Monitoring Portal

- Simplifies cryo freezer maintenance across your lab or enterprise

- Empowers real-time cryogenic storage system monitoring at any time and from anywhere in the world

- Communicates critical at-a-glance metrics with text or email alerts if conditions change

FreezerPro Inventory Management

- Facilitates inventory tracking, robust reporting, detailed searches, and audit trails

- Seamlessly integrates with CryoArc Software, along with other Azenta automated storage systems and devices to enhance cold chain management convenience

- Supports 21 CFR Part 11 compliance along with Parts 21, 58, 210, cGLP/cGMP, and Section 508 accessibility guidelines

- Offers high security with remote access

- Scales to the changing needs of lower throughput labs up to large central biorepositories

Scale and Change at Your Pace

As a market-leading automated cryogenic storage system, CryoArc Tera easily adapts to your lab’s size and needs.

- Accepts a wide range of labware

- Single interface and familiar software when adding multiple units – including our small-collection CryoArc Pico, medium-collection CryoArc Deca, and cell and gene therapy production-level CryoArc Tera for Cassettes models – to your lab or enterprise

- Efficient space use and rapid system integration

Round out your workflows with additional high-performing Azenta cryogenic tools:

Extend Cryogenic Storage Confidence

- Flexible Support Plans keep your CryoArc Pico investment running at peak performance

- Trainings develop your team’s skillsets with applicable knowledge

- Qualification Services (IQ/OQ/PQ) help you achieve compliance requirements

- Equipment Repair, Refurbishment, or Relocation on request